StudentShare

Our website is a unique platform where students can share their papers in a matter of giving an example of the work to be done. If you find papers

matching your topic, you may use them only as an example of work. This is 100% legal. You may not submit downloaded papers as your own, that is cheating. Also you

should remember, that this work was alredy submitted once by a student who originally wrote it.

Login

Create an Account

The service is 100% legal

- Home

- Free Samples

- Premium Essays

- Editing Services

- Extra Tools

- Essay Writing Help

- About Us

✕

- Studentshare

- Subjects

- Health Sciences & Medicine

- General Property Requirements of Stent Fractures

Free

General Property Requirements of Stent Fractures - Research Proposal Example

Summary

The paper "General Property Requirements of Stent Fractures" highlights that several perspectives came up in the findings with commendations to the assessment of stent fractures. It is taken that biomechanical forces that are dynamic such as torsion, bending, tension, causes stent fractures…

Download full paper File format: .doc, available for editing

GRAB THE BEST PAPER92.1% of users find it useful

- Subject: Health Sciences & Medicine

- Type: Research Proposal

- Level: Undergraduate

- Pages: 5 (1250 words)

- Downloads: 0

- Author: willis32

Extract of sample "General Property Requirements of Stent Fractures"

1. Background and motivation All over the globe, the dominant cause of deaths and serious illness - which accounts to 30% of the deaths recorded annually – is cardiovascular diseases. These diseases lead to stent, which is an emerging treatment of an expandable metal mesh tube put into the blocked coronary artery 1,2. The rate of artery blockage declined substantively from 30%–40% to approximately 20% after applying stents 3. Unfortunately, several patients depicted in-stent restenosis (ISR). For instance, artery blockage, due to the thick accumulation of vascular tissue after the placement of stent 1,3,4. Hence, stent fractures (SF) still remain a concern 3-5.

1.1. General property requirements of stents

Quality stent material must be resistant enough to corrosion, visible in X-rays and Magnetic Resonance Imagining (MRI). Therefore, cobalt chromium alloy L605 and stainless steel 316L are popular metals in the biological and medical field, whose biomedical application is coronary stent 2,6,7. The metals are characterized with excellent rusting resistance, high modulus of elasticity 6 and a high degree of ductility 7,8 compulsory to resist deformation during expansion. Finally, the ratio of yield strength to modulus of elasticity 8 is of importance for stent designer as it characterizes the elastic range of the materials, which affects acute recoil and radial strength. Even though an ideal combination of mechanical traits discussed above is difficult to obtain, a careful balance needs to be found 8. Table 1 below gives a summary of the main physical and mechanical properties for common stents materials.

Table 1: Physical and mechanical properties of selected biomaterials 9

Material

Density (g/cm³)

Elastic Modulus (MPa)

UTS (MPa)

Yield Strength (MPa)

Elongation (%)

316L Stainless steel

7.95

193

670

366

43

Co-Cr alloy

9.1

243

1147

629

46

1.2. Assessment of stent fractures

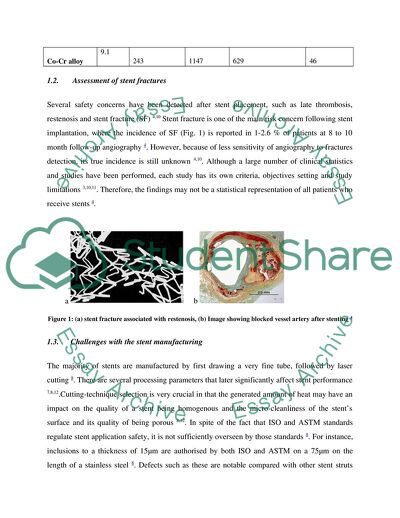

Several safety concerns have been detected after stent placement, such as late thrombosis, restenosis and stent fracture (SF) 4,10 Stent fracture is one of the main risk concern following stent implantation, where the incidence of SF (Fig. 1) is reported in 1-2.6 % of patients at 8 to 10 month follow-up angiography 4. However, because of less sensitivity of angiography to fractures detection, its true incidence is still unknown 4,10. Although a large number of clinical statistics and studies have been performed, each study has its own criteria, objectives setting and study limitations 3,10,11. Therefore, the findings may not be a statistical representation of all patients who receive stents 4.

a

b

Figure 1: (a) stent fracture associated with restenosis, (b) Image showing blocked vessel artery after stenting 4

1.3. Challenges with the stent manufacturing

The majority of stents are manufactured by first drawing a very fine tube, followed by laser cutting 8. There are several processing parameters that later significantly affect stent performance 7,8,12.Cutting-technique selection is very crucial in that the generated amount of heat may have an impact on the quality of a stent being homogenous and the micro-cleanliness of the stent’s surface and its quality of being porous 8,12. In spite of the fact that ISO and ASTM standards regulate stent application safety, it is not sufficiently overseen by those standards 8. For instance, inclusions to a thickness of 15μm are authorised by both ISO and ASTM on a 75μm on the length of a stainless steel 8. Defects such as these are notable compared with other stent struts thinner than 100μm 8,13 and have a high affinity to stent fracture. Inclusions have become increasingly precarious with the tendency in the direction of stronger materials, micro vessel stenting and decrement in dimensions of the struts 1,8.Moreover, when choosing a source for cutting, scrutiny should be given to the composition of chemical homogeneity and heat consistency that favours uniformity in mechanical properties 8,12.

Other key aspects in the performance of stents is to provide having a suitable amount of control during the process of tube drawing 8,12. Generally, accuracy in dimensions and surface finishes varies largely in relation to the process of tubing and the alloy type being selected 8,12. Uniformity in stent thickness is important for smooth stent deployment 2,8,13. Subtlety to handling parameters is divergent from one material to another 8,9.Stainless steel displays reduced sensitivity to the processing parameters as compared to alloys of Co-Cr8,9. Fortunately, such sensitivity gives manufacturers an opportunity to change the material constituents to the needed requirements 8. After the electro-polishing and cleaning steps, surface finish needs to be suitable in obtaining the desirable stent finish 8,12. Such operations conflict among some stent manufacturers, as per the constituent of material removed 8.

It is important to understand that different manufacturers of stents have different hardening plans 8,12. Nonetheless, the favoured standard regulation would be to cut with laser the cold worked materials, followed by hardening 8. This approach helps to subtract the unwanted surplus stresses created amid the laser cutting 8,12. Yet, hardening needs to be correctly managed to acquire the desirable microstructure and mechanical properties 8.

1.4. Reasons for stent fracture

Several perspectives came up in the findings with commendations to the assessment of stent fractures. It is taken that biomechanical forces that are dynamic such as torsion, bending, tension, and compression, working on superficial arteries causes stent fractures 3,14.

Some common observations are that the high percentages of stents that were fractured were lengthy 3 or released in a super-imposed manner 3,10. As written by Halkin et al., 15 cases of cardiac motions and stents overexpansion are important aspects that influence a stent’s durability post-deployment. In a report documented by Min et al., 16 an SF case in which angularity of vessels is another admissible aspect in SF. Excessive vessel asymmetry causes increased bending points amid potent changes in cardiac cycles 3,16, thus stent placements at some angulated parts in the vessel shows a rise in the incidences of SF 3.

Corrosion may crop up in human bodies, hence eroded sites can then develop into inception sites for a fracture 6,17. Below, Figure 5 shows cases of pitting attrition of stents of nitinol crippling the stents struts, subsequently developing to fractures of the stent struts under ambient undulation 17. Further work needs to be performed to improve alloy corrosion resistance 6.

Figure 5: Example of nitinol wire corrosion pits shown by SEM 17.

2. Problem statement

Initial reports have referred to stent fracture (SF) as an undesirable events and life threatening 18-20. Indeed, there is mounting evidence that relates complete SF with in-stent restenosis (ISR) (blockage) with stent functional failure and potential immense effects 4,10,20,21. Nonetheless, SF is still clinically difficult to detect because of the limited visibility of imaging modalities 4. Clinically speaking, the incidence of stent fracture is reported in 1-2.6 % of patients 11,20,22. With Higher rates (up to 29%) reported based on pathological investigations (i.e. SF are assessed when patient is dead) 4. From a material engineering point of view, complete SF can be associated with implant duration i.e. Complete SF may occur with the longest implant duration 23,24. This suggests a fatigue phenomenon related with the dynamic loading of the stent due to blood pressure. In principle, achieving smaller grain sizes is one factor in improving fatigue resistance 8,25. However, conventional thermo-mechanical processes can reduce grain size but only to a certain size. This is often of the order of magnitude of the stent strut cross section. This may lead to poor fatigue performance 8. The current stent strut cross sections are approximately (100-70) µm which allows only for few grains across, since the material grain size is about 30-50 µm, thus affecting its fatigue resistance 8,11,26-29. Indeed, smaller grain size is recognized in the biomedical domain and has definite benefits for both strength and wear properties 30. Therefore, surface mechanical abrasion treatment process is proposed as the manufacturing process since it can generate finer grained microstructures, of the order of a few nanometres, in comparison to the conventional stent materials. Finally, the heat of the conventional laser machining is also associated with grain roughening at the surface of the stent which affects it mechanical properties 8,31,32.

The aim of this research proposal is to confirm the feasibility of using surface mechanical attrition treatment (SMAT) to better the properties of stents relevant to their functions, namely fatigue, ductility, strength, and abrasion resistance. Therefore, the aim is to develop a cardiovascular stents capable of enduring the heart’s high pumping pressure, variation in vessel size and reduced rate of stent fracture by performing SMAT of stent material as it provides increased strength and better resistance against dynamic pressures.

Read

More

sponsored ads

Save Your Time for More Important Things

Let us write or edit the research proposal on your topic

"General Property Requirements of Stent Fractures"

with a personal 20% discount.

GRAB THE BEST PAPER

✕

- TERMS & CONDITIONS

- PRIVACY POLICY

- COOKIES POLICY